aro

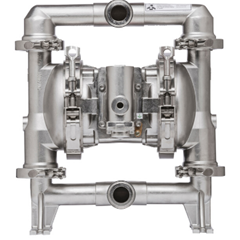

ARO air operated double diaphragm pump (AODD pumps) are designed for general fluid transfer. Our diaphragm pumps reliably transfer a wide variety of fluids, from clean, light viscosity to medium viscosity. They can pump large particles without damage.

Metal or plastic diaphragm pump casings can easily handle corrosive and abrasive fluids. Most ARO diaphragm pumps are ATEX certified (CE Ex11 2GD X).

PRODUCT INFORMATION

There is a wide range of products in the air operated double diaphragm pumps, ARO.

WORKING PRINCIPLE

Air operated diaphragm pumps are classified as positive displacement pumps and use 2 flexible diaphragms that move back and forth. They create a temporary space that serves to draw in and produce fluid through a pump. The two diaphragms act as a separating chamber between air and fluid.

First stroke

The two diaphragms are connected by a shaft through the center where the air valve is located. The purpose of this air valve is to concentrate compressed air toward the back of the initial diaphragm, causing it to move away from the center. The second diaphragm performs the inhalation process, and the air behind is brought out into the atmosphere.

When this occurs, the suction ball is pushed away from its seat - allowing fluid to flow through the ball valve into the fluid chamber.

Second stroke

When the initial diaphragm has reached the end of its stroke, air movement is diverted from the initial diaphragm to behind the second diaphragm by the air valve. Compressed air forces the second diaphragm away from the middle block, which causes the initial diaphragm to be pulled toward the middle block. In the second pump chamber, the discharge ball is pushed from its holder, whereas in the initial pump chamber it is the other way around. When this blow ends, the air valve concentrates the air back into the back of the initial diaphragm and starts the cycle again.

APPLICATIONS

- Chemical processing

- Oil & Gas

- Food & Beverages

- Flavour & Fragrances

- Pharmaceutical

- Pulp & Paper

aro fda pump

ARO compact diaphragm pumps feature flow rates up to 33 GPM (125 LPM) and offer a wide range of material and porting configurations. EXP Series pumps are available with Electronic Interface capability, solenoid actuation for accurate cycle rate control, and long-life PTFE diaphragms, providing a 2-time increase in service life over standard PTFE*.

ARO EXP series Pumps

The ARO compact diaphragm pumps have flow rates up to 33 GPM (125 LPM) and offer a variety of material and port configurations. EXP Series pumps are available with Electronic Interface capability, solenoid actuation for precise cycle rate control, and a durable PTFE diaphragm, providing a 2-fold increase in life over standard PTFE*.

ARO pro series Pumps

ARO Pro Series air operated diaphragm pumps are ideal for general industrial and OEM installation applications. They can easily pump from clean, light viscosity fluids to corrosive, abrasive medium viscosity fluids and can transfer large particles without damage. Due to their pneumatic motor, they could be used in potentially explosive areas. Most of the ARO diaphragm pumps are ATEX certified (CE Ex11 2GD X).