Verderflex Peristaltic Hose pumps and Tube pumps are the ideal solution for pumping liquids and dosing applications. Ranging from smaller industrial pumps to the world’s largest hose pumps used in very heavy industrial and mining applications.

Verderflex VF

Powerful high flow, high pressure pump. Robust Verderflex VF hose pumps are excellent for pumping viscous, abrasive or corrosive fluids and can be ATEX certified.

Verderflex Dura

Compact, low to medium flow high pressure pump. The Verderflex Dura is the most compact peristaltic pump in the market. Thanks to the innovative design the footprint can be reduced up to 70%.

Verderflex Vantage

Precision, controlled dosing .The Verderflex Vantage is a very precise, controllable dosing system with a USB back-up. Ideal for dosing abrasive, corrosive, shear sensitive and viscous fluids. Several control options and pump heads are available for this pump series.

Verderflex Rapide

Simple low pressure industrial dosing. These simple IP55 industrial style pumps can be easily integrated into existing equipment. They are ideal for liquid transfer and can be easily controlled by external inverters (VFD's).

Mining

Verderflex peristaltic pumps are the first choice for mines around the world, offering unrivalled performance in a tough and uncompromising environment.

Only hose pumps can pump abrasive mining slurries with up to 80% sub-micron solid contents with dense slurry SGs > 2.0. They substantially reduce water use by up to 4 times the volumes needed by other pumps.

Pump up to 80% Fine Solids in

Ideal for Slurry transfer

Substantially Reduces Water Use

Reduces process water by up to 4, No gland water needed

Can Dry Run

No damage if supply line runs dry

Pumps for the mining industry

Verderflex peristaltic pumps are manufactured in the EU within ISO 9001, ISO 14001 and ISO 45001 accredited facilities.

Verderflex® Dura

The Verderflex Dura is a true 2nd generation pump : the first real advance in hose pump technology since the high pressure hose.

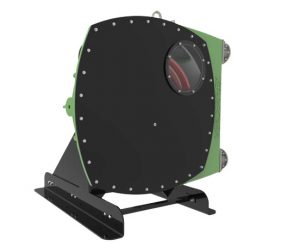

Verderflex® VF

The original Verderflex peristaltic hose pump series is now solely focussed on high flow applications and includes the widely used VF125, the world's largest high pressure hose pump.

Heavy duty slurry pumps for the mine

In dosing galleries, the variable nature of the corrosive reagents causes diaphragm pumps to clog leading to increased chemical usage and lower plant efficiencies, whereas progressive cavity pumps suffer from burnt stators as they are allowed to run dry.

This has lead to peristaltic pumps being specified in floatation cells, primary mineral and tailings retreatment plants and heap leaching installations worldwide.

The rubber hose is capable of pumping slurries containing:

- Pyrite

- Copper concentrate

- Uranium

- Nickel

- Cobalt

- Silver

- Platinum

- Chrome

- Gold concentrate

Peristaltic hose pumps have many applications in the mine:

- Slurry transfer

- Thickener underflow recirculation

- Reagent dosing

- Froth flotation

- Cyanide processing

The Verderflex VF125 is the world’s largest high pressure hose pump and can of pump high SG slurries at over 60m³/hour or 260 GPM. The Verderflex VF125 and VF100 are both ideal for the heaviest duty tasks such as circulating slurry and thickener underflow.

Chemicals

When pumping hazardous chemicals it is important to use a leak free pump that resists the chemical’s corrosive effects.

Pump difficult liquids

Solids in suspension, thick viscous liquids, aggressive chemical solutions pumped with ease

Precision dosing

Ideal for abrasive slurries, flocculants or offgassing liquids

Can Dry Run

No damage if supply line runs dry

Applications

The varied chemical industry has many pumping challenges - abrasive liquids, aggressive chemicals, minimal ancillaries, gentle pumping actions, accurate process addituions, crystallisation.

Pumps for the chemical industry

Verderflex peristaltic pumps are manufactured in the EU within ISO 9001, ISO 14001 and ISO 45001 accredited facilities.

Verderflex® Dura

The Verderflex Dura is a true 2nd generation pump : the first real advance in hose pump technology since the high pressure hose.

Verderflex® Vantage 5000

The Verderflex Vantage 5000 family is the next generation in precision dosing and dispensing pumps.

Verderflex peristaltic pumps for the chemical industry have :

- Total fluid containment with no seals

- Hose and tubes giving extensive chemical compatibility

- Extended tube or hose life and reduced maintenance

- Continuous dry running and excellent self-priming capabilities

- Highly accurate and repeatable metering and dosing performance

Verderflex peristaltic hose or tube pumps are capable of pumping many different chemicals, including:

- Sodium hypochlorite

- Sodium hydroxide

- Calcium hydroxide

- Cyanide solutions

- Plating solution

- Catalytic agents

- Sulphuric acid

- Solvents and resins

Food and Beverage

Food products such as dairy, baked goods, cereals, beverages and confectionary demand pumps that meet today’s hygiene standards and are able to handle products with care.

Precision dosing

Ideal for abrasive slurries, flocculants or offgassing liquids

Gentle low shear pumping

Avoids damaging the pumped product and maintains flavour structures

Low heat pumping

Low pumps speed avoids heating up the pumped product

Applications

The food and beverage industry has a mixture of pumping demands - hygienic pumping, low maintenance and minimal contamination risks - Verderflex has a range of peristaltic pumps to address these varying demands.

Pumps for the food and beverage industry

Verderflex peristaltic pumps are manufactured in the EU within ISO 9001, ISO 14001 and ISO 45001 accredited facilities.

Verderflex® Vantage 5000

The Verderflex Vantage 5000 family is the next generation in precision dosing and dispensing pumps.

Hygienic, food grade tube and hose pumps and food pumps

Peristaltic tube pumps are perfect for sanitary pumping of many foods and liquids. The gentle pumping action works well with shear sensitive products and products that offgas, such as when pumping yeast in brewing beer.

Clean in place (CIP) and sterilisation in place (SIP) are essential in the manufacture of food. Peristaltic pumps allow you to clean in line without the need for further dismantling of the pump, saving time and reducing cost.

There is no risk of bacterial growth in a tube pump as the products is fully contained within the tube, nor are there are any dead spots where bacteria can accumulate. The pumping action means the tube is swept fully and the pump can self drain.

Additionally, food grade tubing can be sterilized by all normal methods of sterilisation including radiation, steam and chemical solution allowing local confirmation of process sterility and with the easy to change tube the only contact part then routine sterilization costs are kept to a minimum.

Paper, Pulp, Printing & Packaging

Verderflex peristaltic pumps offer optimum performance to the printing and packaging industries. Combining the ability to self-prime, run dry and an ultra-fast tube changeover these pumps keep downtime to an absolute minimum.

Gentle low shear pumping

Avoids creating bubbles in inks and colourants

Reversible pumping

One pumps can feed the print head and recover inks at the end of a batch

Reduced energy costs

Zero air requirement eliminates air costs and compressor maintenance charges

Applications

Print and packaging customers have ever increasing quality demands : producers must avoid rejected batches because of bubbles whilst economic demands pressurise operating costs - Verderflex pumps can help improve operational performance

Pumps for the printing and packaging industry

Verderflex peristaltic pumps are manufactured in the EU within ISO 9001, ISO 14001 and ISO 45001 accredited facilities.

Verderflex® Dura

The Verderflex Dura is a true 2nd generation pump : the first real advance in hose pump technology since the high pressure hose.

Verderflex® Rapide

The Verderflex Rapide range of Industrial tube pumps are compact, simple to operate low pressure peristaltic pumps

Verderflex Vantage 3000 and Smart tube pumps can to be used as standalone pumps, providing extremely accurate dosing with high repeatability on flow rates from a few millilitres per minute up to 17 litres per minute.

Alternatively the Verderflex OEM and Industrial Hose and Tube ranges offer custom designed tube pumps that can be integrated into 3rd party machinery.