gear pump

Gear pump uses the meshing of gears to pump fluid by displacement. Gear pumps are commonly used for pumping high viscosity fluids such as oil, paints, resins or foodstuffs.These pumps are divided into two types. They are internal gear pump and external gear pumps

PRODUCT INFORMATION

There are wide range of products in GEAR PUMPS.

Gear pumps comprise of two main classifications, firstly internal gear pumps, secondly external gear pumps. In this article we will discuss how the internal gear pumps work. This gear pump have rotor and idler assembly. Rotor of gear pumps are integrated part to the shaft. Idler or internal gear is the small gear inside the pump casing. There is some gap between rotor and idler, called as "clearance". The flexible coupling connect the electric motor shaft to rotors shaft. When electric motor rotate the rotor also rotate and create low pressure zone at the pump inlet, so it draws the liquids in to the pump. The fluids layer become the mediator of rotor and idler to fill the clearance between the rotor and idler. As the rotor rotate and fluids come in to pump inlet, it will fill the clearance and cause idler also rotate without any direct contact with the rotor.

APPLICATIONS

- Chemical Processing

- Foam manufacturing

- Construction Materials

- Asphalt transfer

- Food Processing

- Oil Exploration and Refining

- Diesel Oil, Fuel Oil transfer

- Wastewater Treatment

PRODUCT

CLICK ON DOWNLOAD

PT. Topy Undercarriage Indonesia

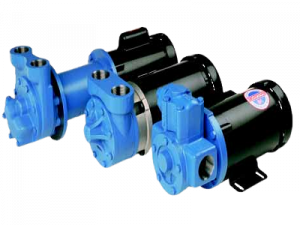

Circulation Pumps - C Series

Model: 2C, 3C, 4C, 5C, 6C

Application(s): Lubrication, Fluid Transfer, Hydraulics, High Temp Applications

Pressures to 300 psi (20.7 bar)

Temperatures to 375°F (191°C)

Viscosities from 32 SSU to 25000 SSU (1 to 5394 cst)

For speeds above 1800 RPM and/or viscosities above 25000 SSU consult factory

1000 Series Lubrication Pump

Model: 1000, 1008, 1010, 1012, 1017, 1018, 1024

1000

Series Lubrication pumps are based on the proven internal gear pump principal, but have been enhanced in response to demands from our OEM customers for a pump that offers advanced features which make installation easier.

These side-ported pumps have the option to bolt SAE/DIN flanges onto them ensuring maximum flexibility on the porting arrangements.

Our goal was to design a pump that meets your technical requirements and is easily fitted into your system.

MAGNETICALLY COUPLED PUMPS

Process upsets and cold starts can result in decoupling and permanent magnet damage that results in costly repairs and unplanned downtime. Using generously sized high temperature magnets can often prevent this situation. That is what Tuthill delivers in the M series magnetically coupled sealless process pumps.

heavy duty(hd) Series

Tuthill offers the HD Series Gear Pumps for the most demanding applications- slurries high-viscosity products, suspended solids, concentrated acids, chemicals, high temperature liquids, sludge, resins, sewage and scum, paints, polymers, plastics pharmaceuticals, foods, and shear sensitive fluids. This rotary positive displacement, circumferential piston pump is Tuthill’s severe-duty problem solver. Its Heavy-Duty construction and ability to run dry indefinitely provide longer lift in the toughest pumping conditions. The Gear Pumps HD series is available in 316 stainless steel or ductile iron.

HD PUMPS

- Capable or running dry indefinitely

- Flow rates to 650 USGPM (148 m3/hour)

- Pressure to 450 psi (31 bar)

- Viscosities to 20,000,000 ssu (4,400,000 cst)

Global gear series

GG SERIES

Gear Pumps are capable of tackling the toughest high viscosity applications, the Global Gear series handles everything from bulk transfer, chocolate and asphalt, to high temperature fluids and chemical processing. With modular construction, maintenance and service have never been easier. Developed with universal parts and features, our patented design reduces stocking inventories by providing alternatives with minimal switching costs.

GG SERIES

- Back pull-out design provides ese of maintenance

- Flow rates to 550 usgpm (124.9m3/hr)

- Pressures to 200 psi (13.8 bar)

- Viscosities to 1,000,000 ssu (220,000 cst.